In the intricate world of mechanical engineering, precision and reliability are paramount. The smooth thrust bearing at B stands out as a cornerstone of efficiency and durability among the myriad components that ensure seamless operation. This article delves deep into the nuances of the it, exploring its significance, applications, and unparalleled advantages.

Understanding the Smooth Thrust Bearing at B

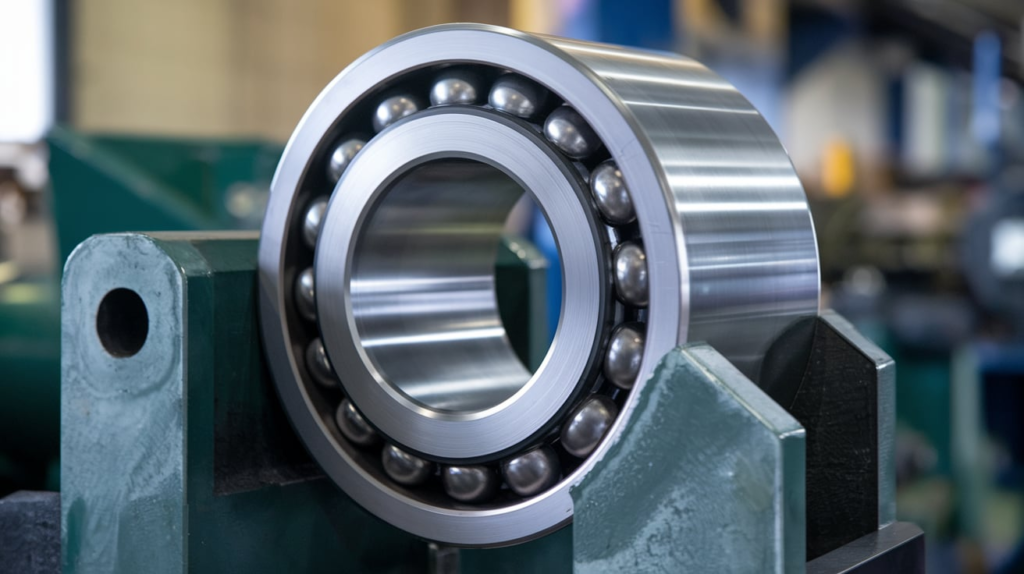

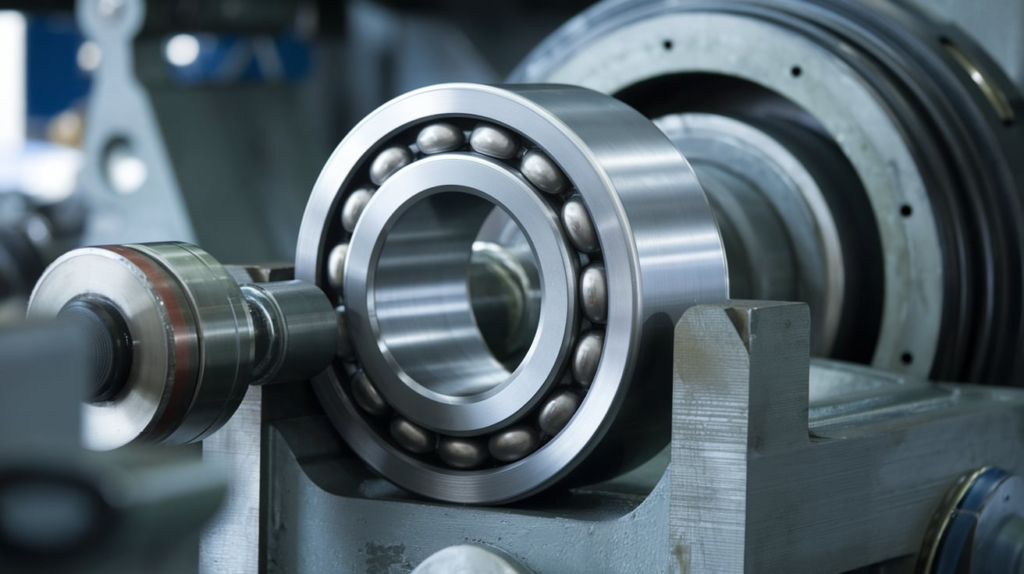

A smooth thrust bearing at B is a specialised component designed to manage axial loads in machinery. Unlike traditional bearings that handle radial forces, thrust bearings are engineered to withstand forces parallel to the shaft. It is distinguished by its refined surface finish, which minimises friction and enhances operational smoothness.

Key Features

The smooth thrust bearing at B boasts several standout features:

- Enhanced Surface Finish: The meticulous polishing process ensures minimal friction and smoother operation.

- Robust Material Composition: Crafted from high-grade alloys, the it offers exceptional durability and resistance to wear.

- Precision Engineering: Each bearing is manufactured with tight tolerances, ensuring optimal performance even under strenuous conditions.

- Versatile Design: The smooth thrust bearing at B is adaptable to various machinery types, making it a versatile choice for engineers.

Applications

The smooth thrust bearing at B finds its application across diverse industries, underscoring its versatility:

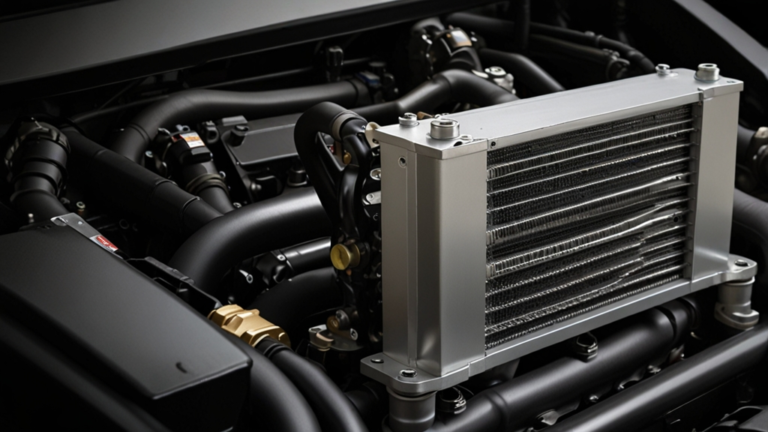

- Automotive Industry: It ensures seamless gear shifts and prolonged component life when used in vehicle transmissions and clutches.

- Aerospace Sector: Critical in aircraft engines, these bearings contribute to the reliability and efficiency of propulsion systems.

- Industrial Machinery: From conveyors to heavy-duty presses, the smooth thrust bearing at B enhances the performance of numerous industrial applications.

- Marine Engineering: The smooth thrust bearing at B is vital in maintaining operational integrity under varying loads in ship propulsion systems.

Advantages of the Smooth Thrust Bearing

Opting for the smooth thrust bearing at B confers multiple benefits:

- Reduced Maintenance: The superior durability of it translates to longer intervals between maintenance checks.

- Enhanced Efficiency: Its low-friction design ensures that machinery operates at peak efficiency, conserving energy and reducing operational costs.

- Extended Lifespan: Resistant to wear and tear, it extends the overall lifespan of the machinery it supports.

- Improved Performance: It effectively manages axial loads, ensuring consistent and reliable performance across applications.

Installation and Maintenance

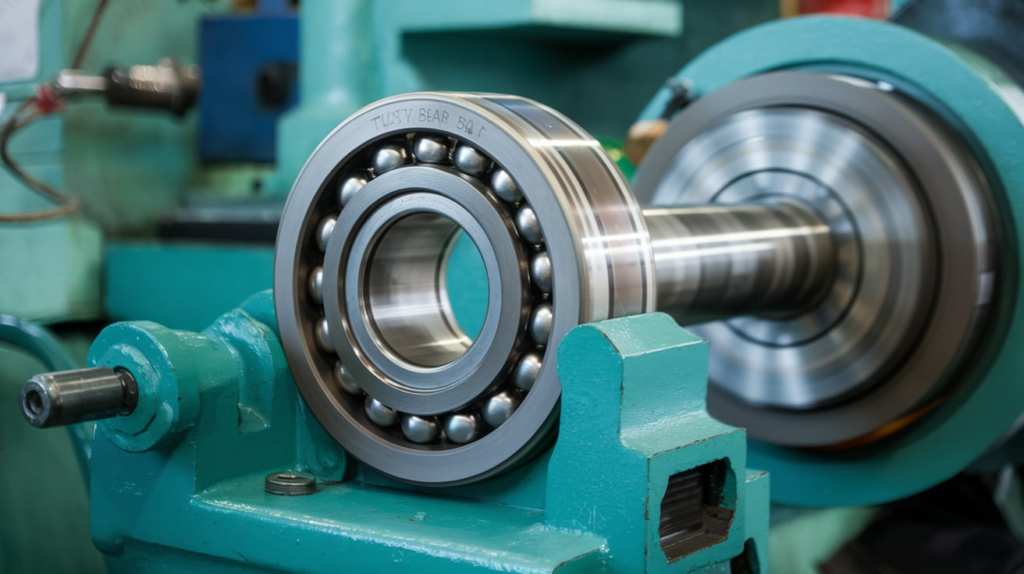

Proper installation and maintenance are crucial to harnessing the full potential of the smooth thrust bearing at B:

- Installation: Ensure precise alignment during installation to prevent undue stress. Utilise appropriate lubrication to facilitate smooth operation from the outset.

- Maintenance: Regular inspections for signs of wear or damage can preempt potential failures. Re-lubrication as per manufacturer guidelines ensures sustained performance.

Selecting the Right Smooth Thrust Bearing

Choosing the appropriate smooth thrust bearing at B involves several considerations:

- Load Requirements: Assess the axial loads the bearing will encounter to select a model with adequate load-bearing capacity.

- Environmental Conditions: Consider factors such as temperature, moisture, and exposure to corrosive elements, opting for bearings with suitable protective coatings if necessary.

- Size and Fit: Ensure the bearing dimensions align with the machinery specifications to guarantee optimal integration and performance.

Future Trends in Smooth Thrust Bearing Technology

Advancements in materials science and engineering drive the evolution of it. Future trends include:

- Innovative Bearings: Sensors within the smooth thrust bearing at B are integrated to monitor real-time performance parameters.

- Advanced Materials: Developing composite materials that offer superior strength-to-weight ratios and enhanced resistance to extreme conditions.

- Eco-Friendly Manufacturing: Emphasis on sustainable production methods to reduce the environmental footprint of bearing manufacturing.

Conclusion

The smooth thrust bearing at B is indispensable in modern machinery, offering unmatched efficiency, durability, and performance. Its sophisticated design and robust construction make it a preferred choice across various industries, driving advancements in mechanical engineering. As technology progresses, the smooth thrust bearing at B continues to evolve, promising even more significant contributions to the realm of machinery and beyond.

(FAQs)

- What distinguishes the smooth thrust bearing at B from other thrust bearings?

The smooth thrust bearing at B features an enhanced surface finish and precision engineering, offering superior performance and reduced friction compared to standard thrust bearings.

- In which industries is the smooth thrust bearing at B most commonly used?

Due to its versatility and reliability, it is extensively used in the automotive, aerospace, industrial machinery, and marine engineering sectors.

- How does the smooth thrust bearing at B contribute to energy efficiency?

Its low-friction design minimises energy loss, ensuring machinery operates more efficiently and conserves energy.

- What maintenance practices are recommended for it?

Regular inspections, proper lubrication, and ensuring precise alignment during installation are crucial to maintaining its performance.

- Can the smooth thrust bearing at B withstand extreme environmental conditions?

Yes, especially models crafted with robust materials and protective coatings, making them suitable for harsh environments.

- Are there eco-friendly options available for it?

Yes, advancements in manufacturing have led to the development of environmentally sustainable it options.